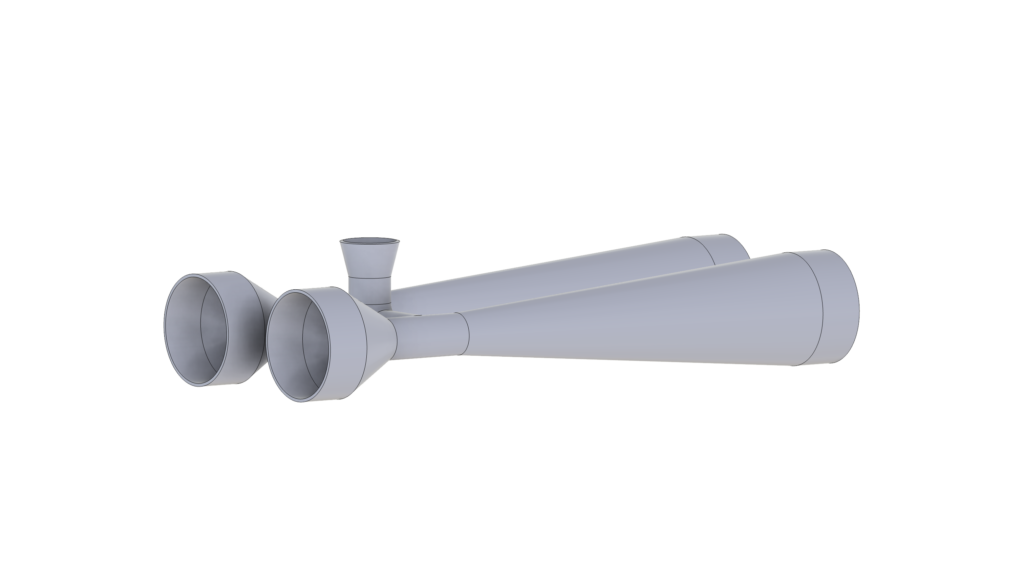

To conduct testing, we have decided to construct our own flume. We purchased a secondhand large acrylic fish tank that measures 1.8 meters long, 600 millimeters wide, and 700 millimeters deep. It will be attached to a tank on either side, using three circulating pumps to achieve a flow rate of 53,000 liters per hour. We anticipate that this setup will be completed by the first week of July.

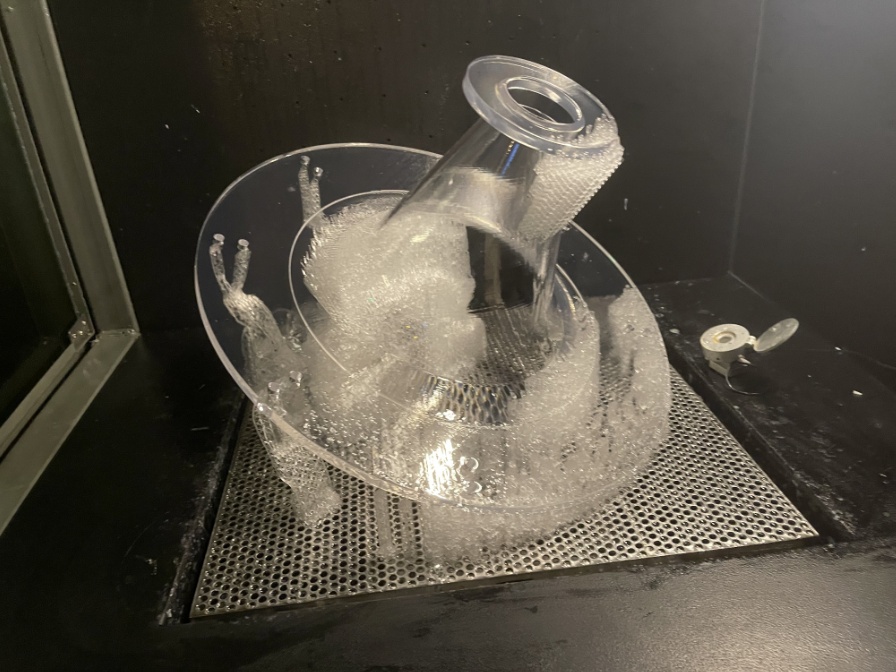

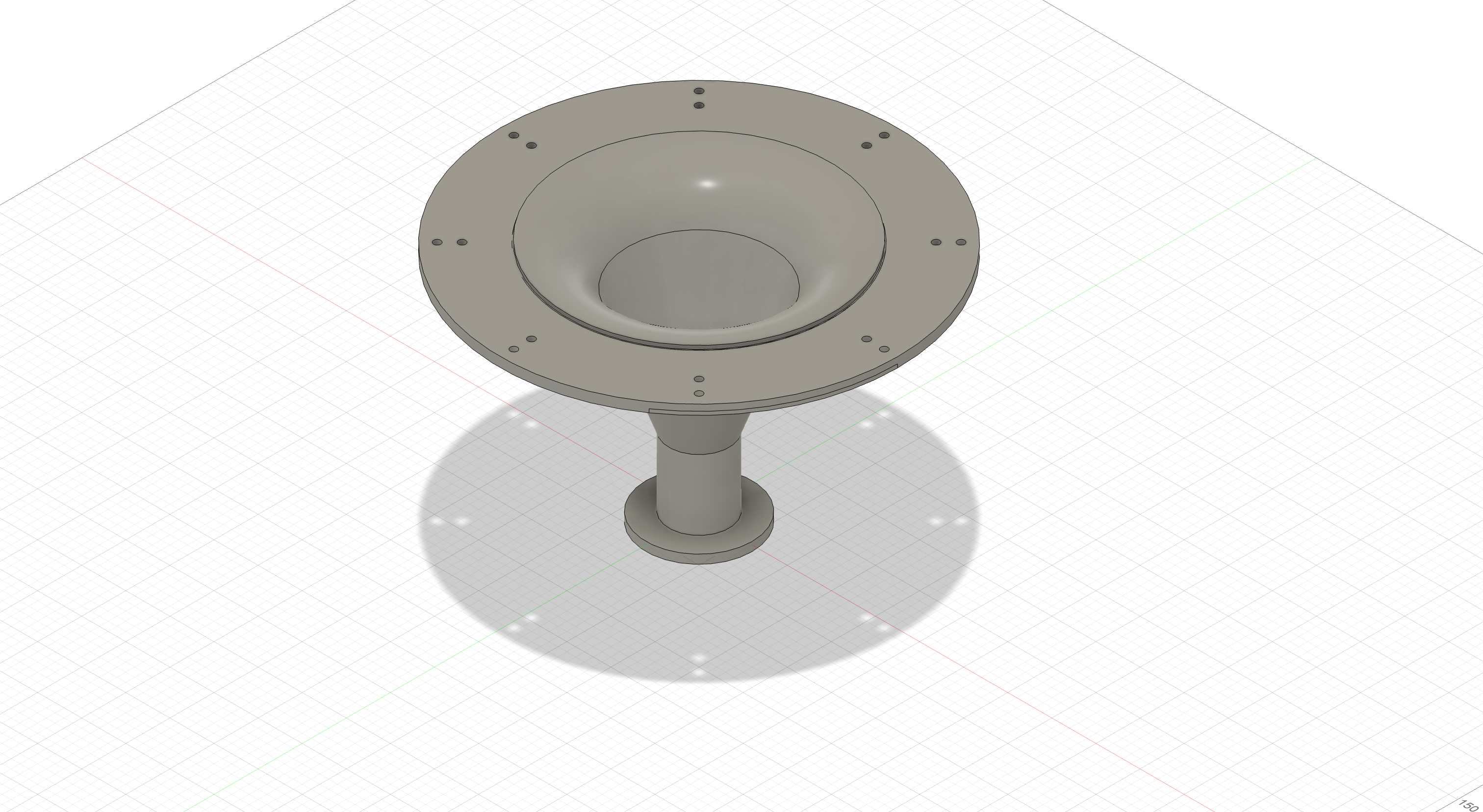

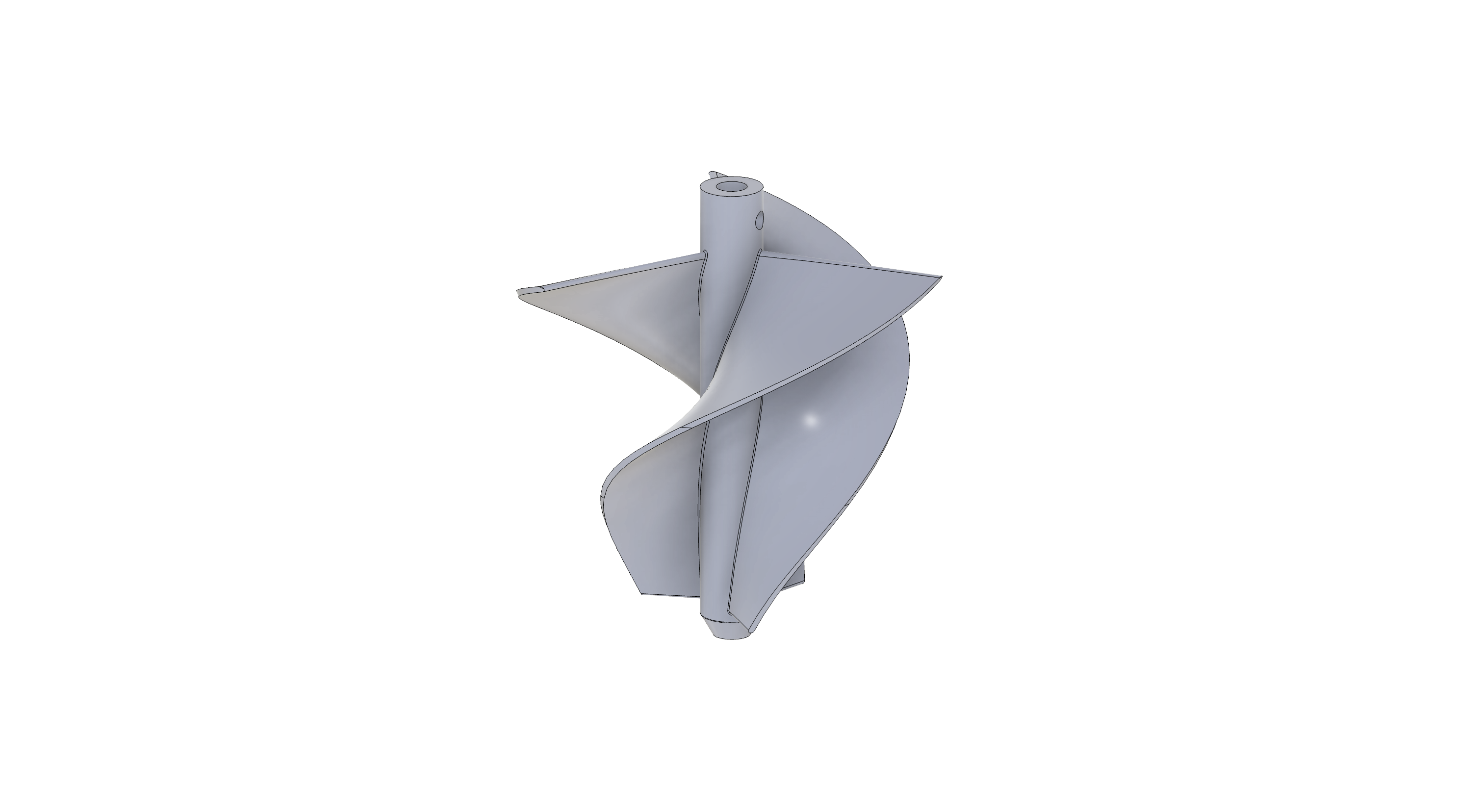

Receiving parts from various manufacturers in mid-June. We receive all components in June and put the new prototype together in early July.